For nearly 60 years, Geostock has built up extensive expertise in all underground energy and CO2 storage techniques, be it for salt caverns, mined caverns, depleted hydrocarbon fields or aquifers (porous media).

Salt cavern storage requires the presence of a significant salt deposit. The cavern is created by dissolving salt in fresh or low-salt water (sea water), a process referred to as “leaching” or “solution mining”. During this process, the shape and volume of the salt cavern are monitored by sonar (echometry). Generally elongated in shape, salt caverns are several hundred metres high and several tens of metres in diameter. They are typically located at a depth of between 200 and 2,000 metres with a volume of several hundred thousand cubic metres.

The stability of salt caverns is ensured by the choice of appropriate geometry and the permanent control of pressures, temperatures and flows during operation. Their tightness relies on the intrinsic properties of salt.

Surface equipment includes one or two well-heads per cavern, compression (for gaseous products), processing and metering facilities.

Stored products

A mined rock cavern is an underground structure consisting of one or more galleries dug into a rock mass (limestone, chalk, granite, etc.). Galleries are typically located at a depth of 50 to 200m. As mined caverns are generally unlined, their tightness is based on the principle of hydrodynamic containment: the caverns are located at a depth enabling the water naturally contained in the surrounding rock to flow towards them at all points. This ensures that the product is contained inside the underground storage facility.

The mined rock cavern technique can also be applied to the cryogenic storage of gases with a liquefaction point below -10°C, with or without a liner. The Lined Rock Cavern (LRC) is suitable for the underground storage of cryogenic products such as CO2 or ammonia (NH3), as well as for the storage of high-pressure gaseous products like natural gas or hydrogen.

The surface equipment includes a well-head, facilities to treat the product and the water extracted from the cavern, metering units, and storage monitoring facilities, such as piezometers and seismic monitoring.

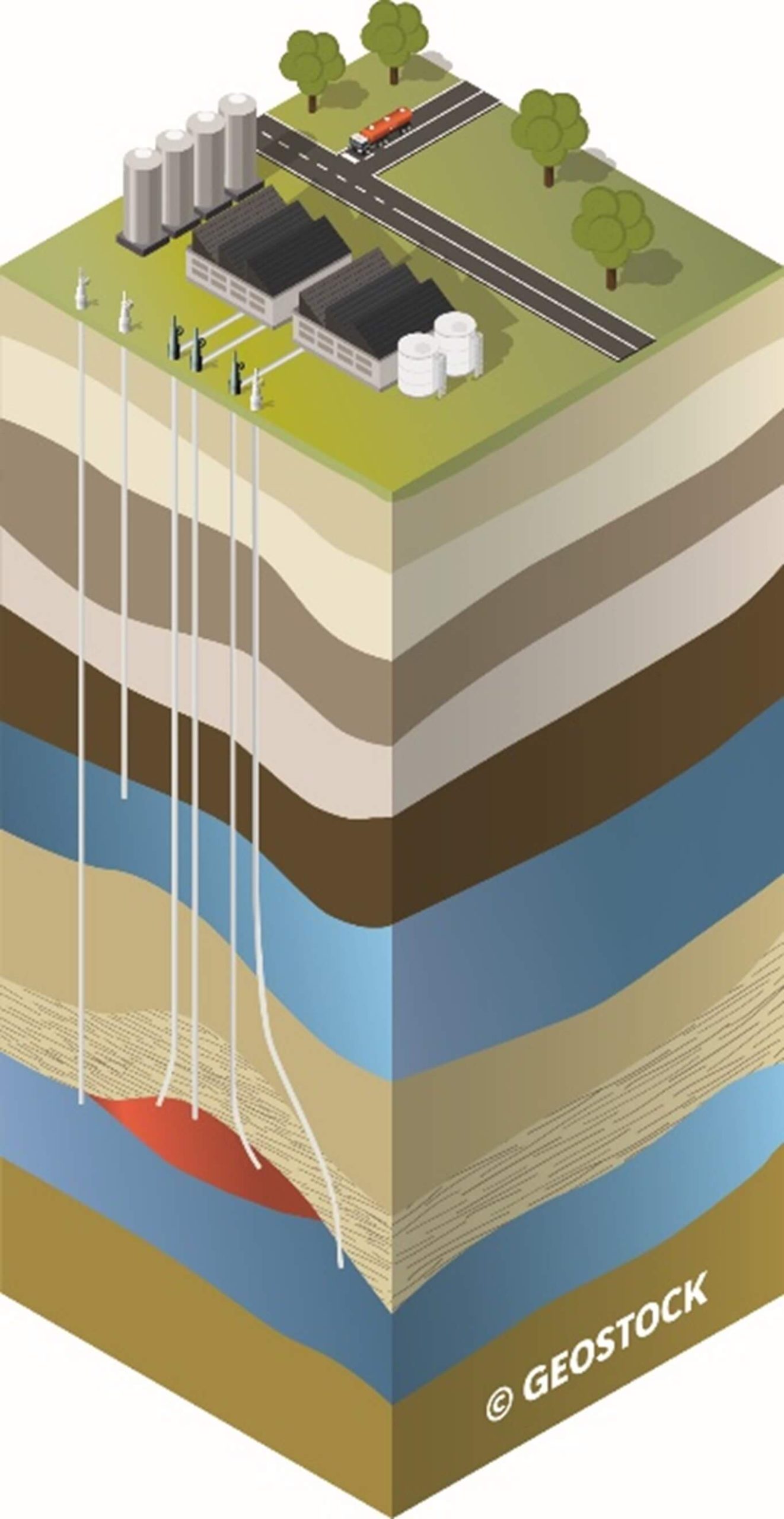

Underground storage facilities in porous media take advantage of a porous and permeable geological formation (the reservoir), be it a depleted deposit or aquifer, topped by an impermeable and structured horizon in the form of a trap.

The porous geological layer is generally located at a depth of between 500 and 2,000 m. In the storage phase, the gas is compressed and injected into the reservoir in a gaseous state through a series of production wells. The gas is then withdrawn under its own pressure. Regarding CO2, the product is generally injected in a supercritical state, i.e. an intermediate state between liquid and gas. The CO2 is permanently trapped.

As with salt-cavern storage, surface facilities include well-heads, compression, processing and metering facilities. Monitoring wells are used to check the position of the gas and the tightness of the underground structure.